CEFEP Technical Blog.

Insulation materials made of FEF and PEF are multifunctional optimisers for the technical equipment of buildings.

Insulation materials made of FEF and PEF are multifunctional optimisers for the technical equipment of buildings.

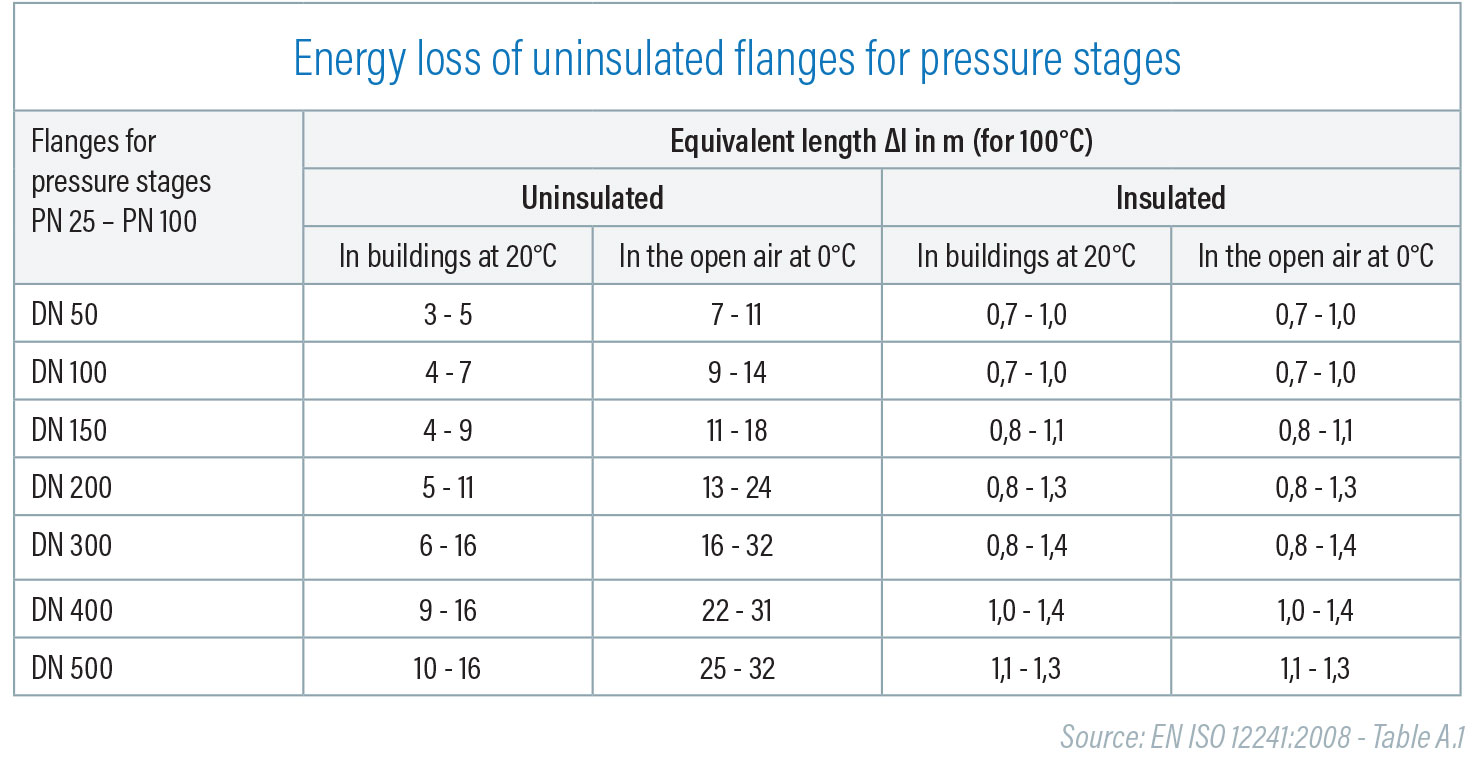

Several EN and ISO standards offer detailed guidance on how to assess just how much additional energy is lost when flanges and other fittings are left uninsulated.

EN ISO 12241:2008 suggests that, depending on the exact location, a single uninsulated flange can yield heat loss equivalent to between 3 and 5 m of insulated straight pipe. That’s an increase in energy loss of at least 300% and potentially as much as 500%.

These energy losses are so great that it’s not possible to "make-up" for them in any other way. Increasing the thickness of insulation applied to straight pipes or selecting insulation with lower thermal conductivity values will save only marginal amounts of energy when compared to the energy savings that can be realised by insulating all flanges, valves and pipe supports using FEF and PEF insulation.

An insulation system only can be as efficient as its weakest points, which makes insulating fixtures like flanges, pipe supports and bends essential. These pipework elements often feature diff icult geometry which is why flexible insulation materials that can be easily fabricated to fit should be the preferred choice for consultants and contractors.

FEF and PEF insulation materials are highly flexible. This makes it possible to insulate even the most complex pipework elements but they offer further, crucial, advantages too. These insulation materials can be easily cut to size on site without the need for specialist equipment – nothing else is needed other than a sharp knife. Since the materials are completely free from dust and fibres they are particularly easy and clean to work with, introducing no contaminants into the working environment.

The insulation of all parts of a pipe and duct system is easy to achieve with insulation products made of FEF and PEF. Due to their flexible, closed cell structure they can easily be cut to fit every part of the pipe system. Only if all parts of a pipe and duct system are insulated properly the mechanical building services can perform most efficiently. This is saving energy and reduces the risk of corrosion every day.